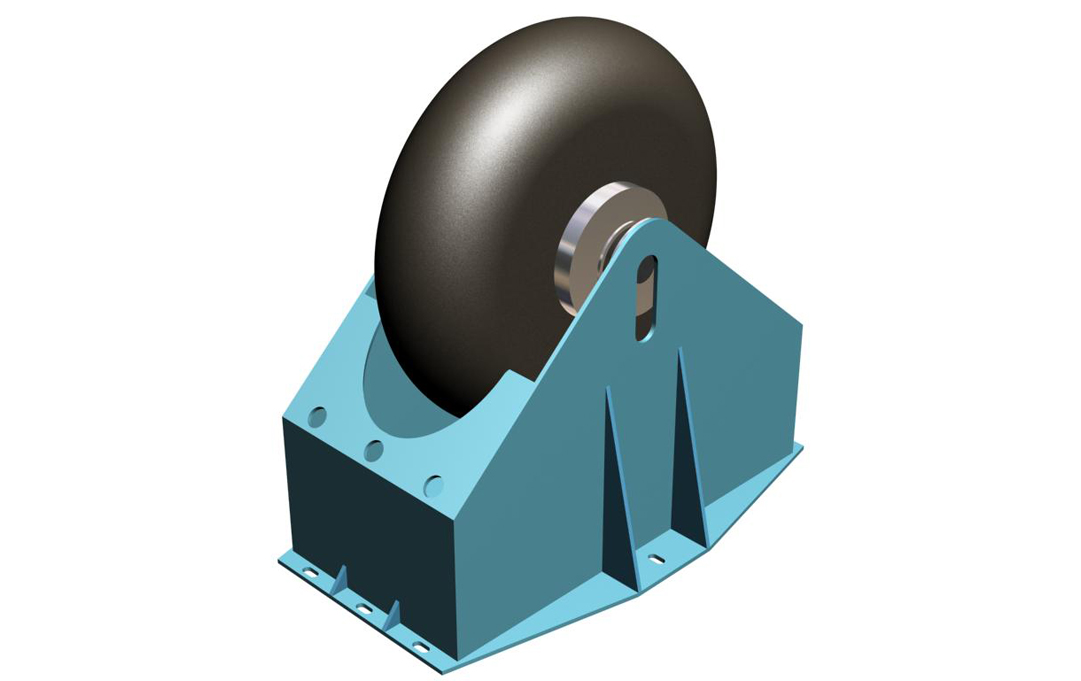

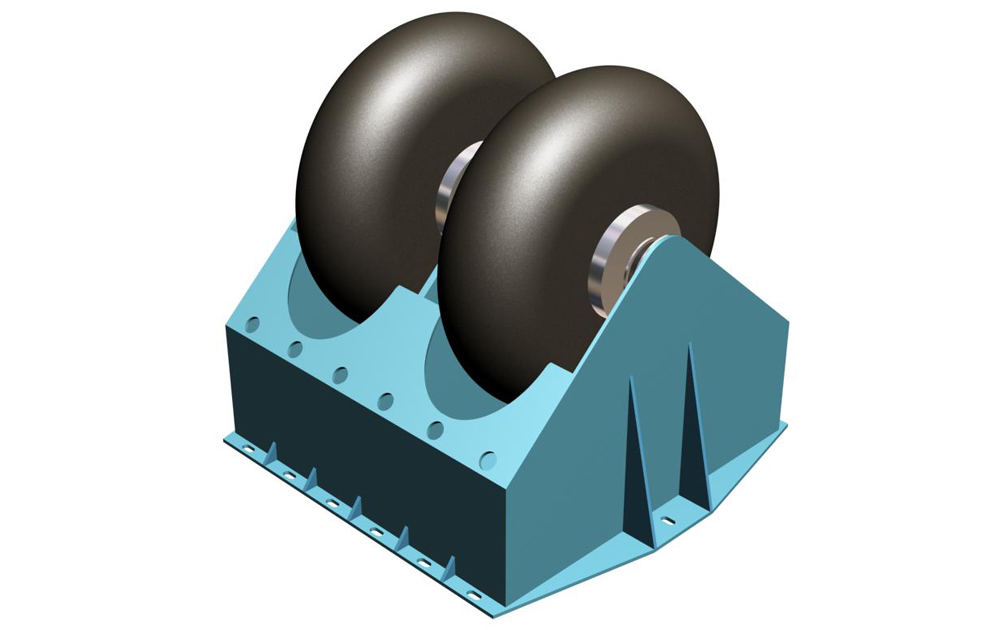

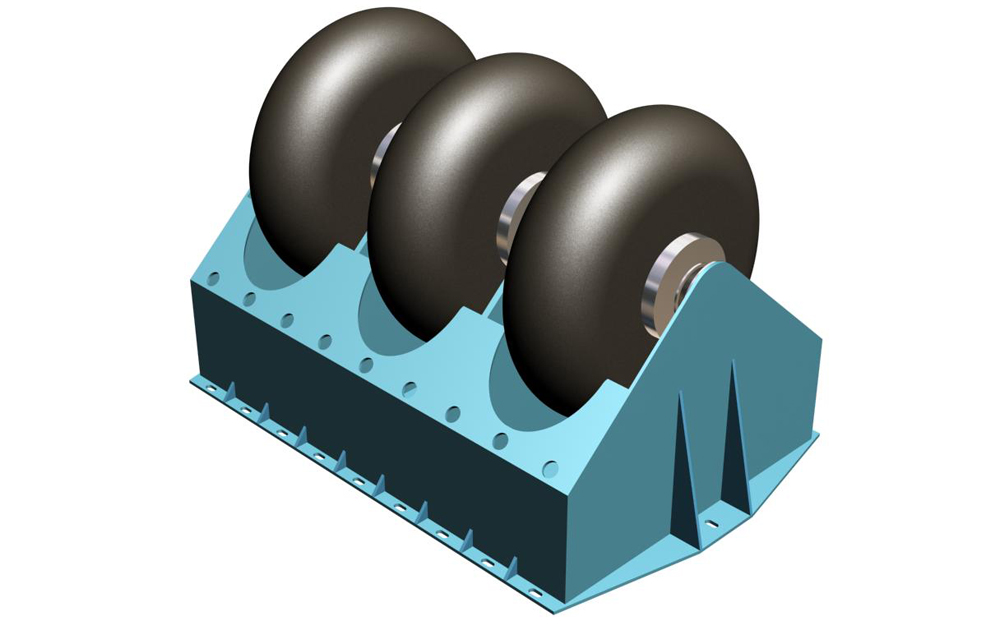

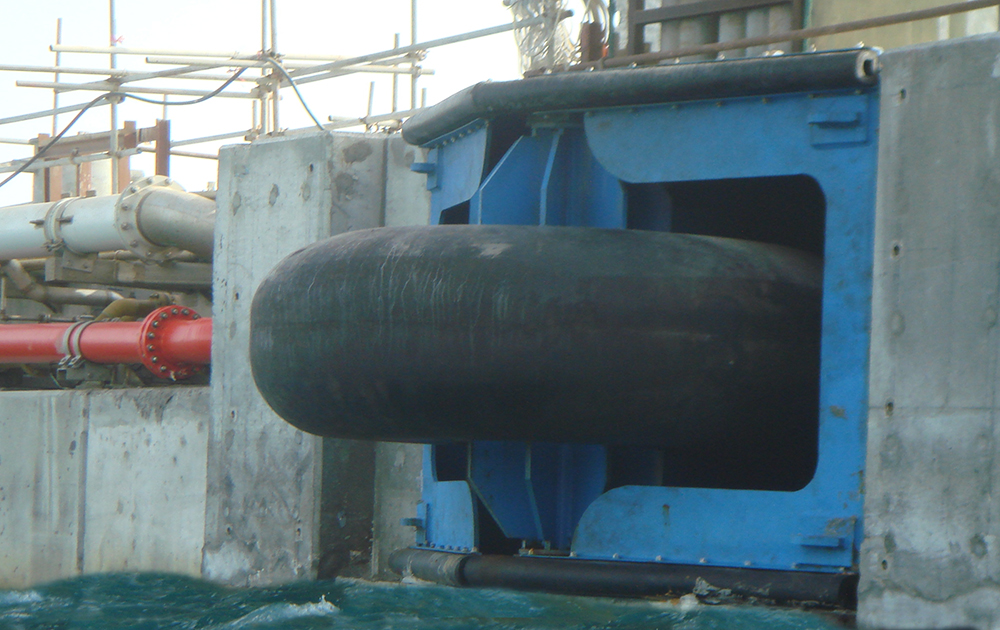

IRM DRF series Roller Fenders are designed to protect the structures while a vessel approaches an entrance channel or comes for dry docking. Unlike D.R. Type fenders, the axes of these fenders are fixed.

IRM Roller Fenders are more resistant to wear and tear by virtue of their capability to rotate in the direction of the impact. These fenders can also be installed vertically to accommodate vessels' rolling and pitching during cargo loading and unloading.

IRM Roller Fenders are manufactured and assembled using a special technology for a uniform deflection of the rollers and a smooth rotational movement in the direction of the force – thus ensuring a safe passage of the vessels without damaging the structure. The superior moulding technology employed in the high-pressure thermic fluid heated hydraulic presses ensures long life and trouble-free performance.

IRM DRF series Roller Fenders are perfectly engineered and assembled in high tensile steel fabricated housing, coated with high-build epoxy paint to ensure trouble-free operations. If required, services can be provided for supervising the installation of the roller fenders.

All roller fenders come with complete details of all parts/components and a Periodic Maintenance and Service Manual, which enables the end-users to get maximum service life.

- Extremely robust and absorbs heavy impacts without any damage

- Neutralizes most of the impact energy

- Copes easily with lateral/grazing loading when the vessels move parallel to the wharf

- Low maintenance design

- Low rolling resistance

IRM DRF series Roller Fenders are available in a wide range from 600mm diameter to 3000mm diameter.

- Dry- Dock entrances and walls

- Lock approaches

- Narrow entries, exits corners