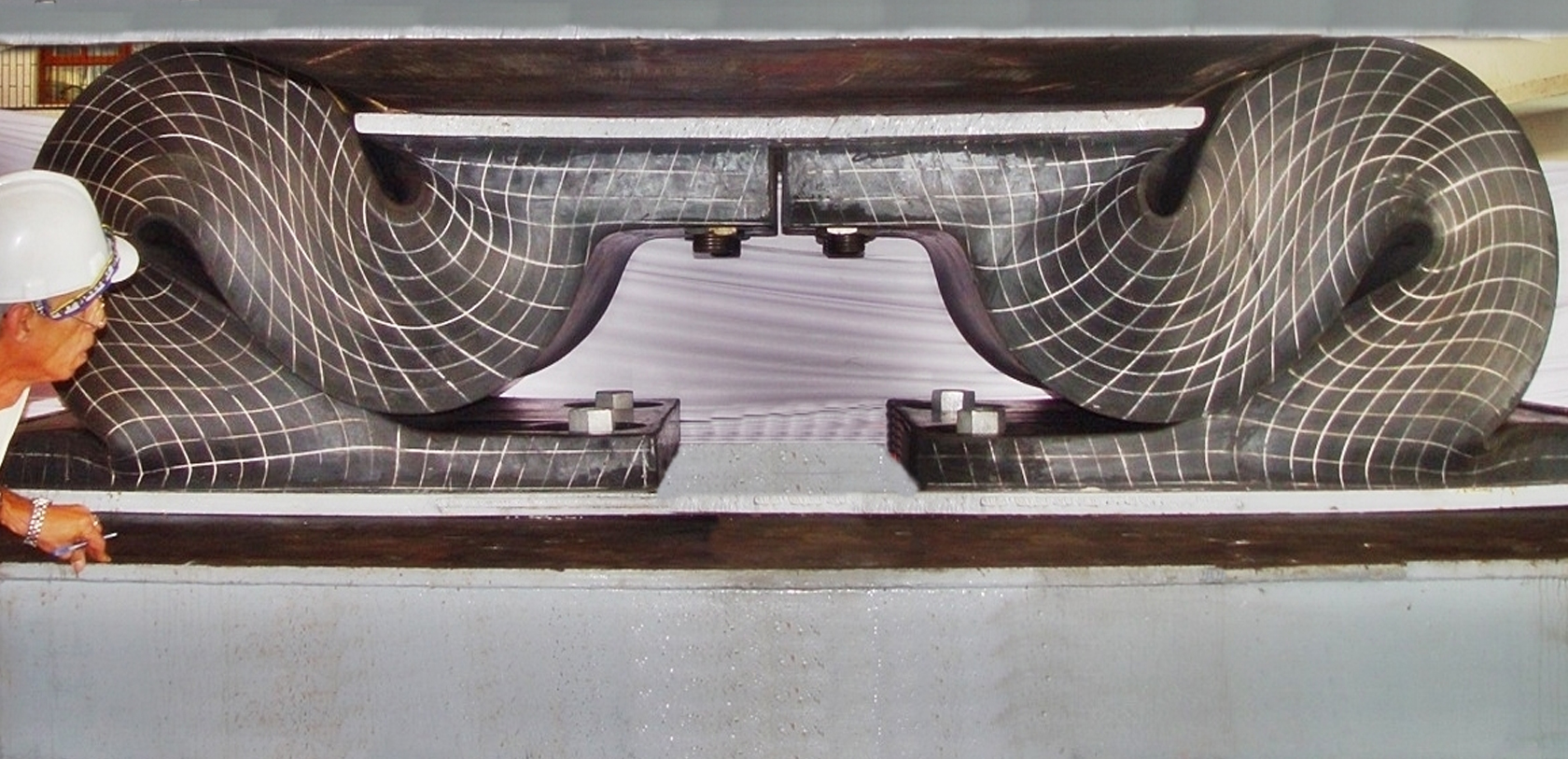

To examine the manufactured product through various phases of production, IRM virtually has every testing facility in house. Load deflection of fenders, hydro test, pneumatic test, leak test, ultrasonic test, cyclic test are some of the tests that ALL products need to pass. IRM has the largest in house quality assurance testing facility to test any type and size of fenders for load-deflection up to 15000 tons in conformance to international standards including PIANC guidelines, which can accommodate any type and size of the fenders available in the World. We test fenders for its full length and not on a pilot cross-sectional sample. We also have facilities to conduct a compression cyclic test for heavy-duty fenders.

IRM has a state-of-art laboratory to test the performance of polymer compounds and finish products for continuous improvement and development of new products. We also employ the expertise of Third-Party Inspection agencies like BUREAU VERITAS, Lloyds, EIL, IRS, DNV, MECON, ISC, Velosi, Germanicher Lloyds, CIPET, etc and independent test houses for various testing and inspection of raw materials/finished products for both physical and chemical properties. Our fully integrated system for perpetual monitoring of raw material, products, and processes to ensure the best quality output is in line with the latest ISO guidelines and recommendations.